You don’t always have the luxury of flat, stable ground when you’re operating earthmoving equipment. Worksites are filled with hills, mounts and dirt piles. Even when working on DIY home earthmoving projects such as building patios, you will likely encounter some uneven turf. Whether working on a professional project or a home renovation, following proper safety procedures for using earth-moving equipment on hills and slopes is important.

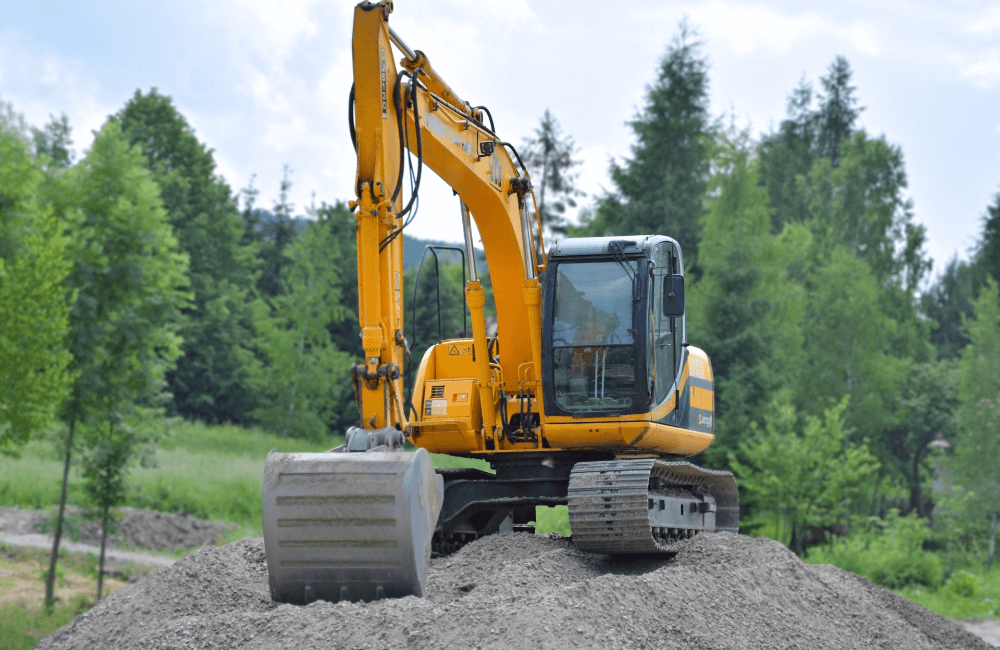

Earthmoving machines such as excavators are capable of climbing steep slopes and inclines, but you have to carry out the task carefully. Excavators are one of the most commonly used devices for earthmoving, yet it’s risky to use an excavator on a steep slope. Traction is a major concern, and if you can’t dig parallel to the tracks pointed downhill and not have the machine slide towards the bucket, that level of traction is unsafe.

Here’s the Ryno Hire guide to using landscaping equipment on slopes to ensure your and everyone else’s safety.

Safety Tips for Using Earth-Moving Equipment on Slopes & Hills

While good earthmoving equipment can handle a lot, it’s always best to err on the side of caution. Here are some safety tips for using earth-moving equipment on hills and slopes:

Survey the scene

It’s important to be aware of any possible dangers that might make your job more complicated, from loose rocks to rocky weather conditions to soil stability. You may have to postpone your work if external factors such as heavy rain make a slope too slippery.

Choose the right machine and know its limits

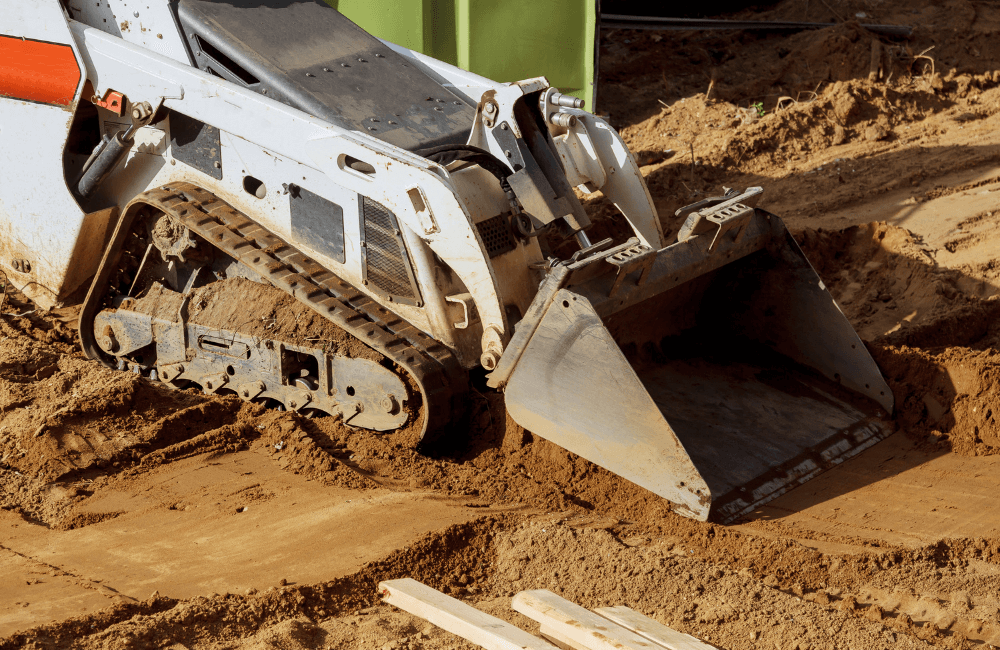

Some earthmoving machinery, such as excavators and bobcat loaders, simply handle slopes better than other kinds. Still, it is important to pick the right machine for the job and to know what your machine can and can’t handle. A slope that’s too steep for a particular machine can cause problems with engine lubrication, for example. One commonly used metric is the 70% rule, which states that any angle greater than 35 degrees is likely problematic.

Keep your tracks pointing up or down, not sideways

Pointing your excavator’s tracks sideways is like trying to walk across a steep slope rather than up or down it. It’s a lot of work and can lead to a nasty fall. To prevent the disaster of a heavy equipment rollover, make sure the tracks stay facing up or down.

Manage the weight of the attachments

Another factor to consider is the extra weight the accessories add to the earthmoving equipment and how they affect its stability. If your earthmoving machine is carrying a lot of extra accessories and weight, balance your load and take it even slower and steadier than usual.

Secure the load

Ensure the load you’re carrying is evenly distributed, properly secured, and doesn’t exceed the equipment’s rated load capacity.

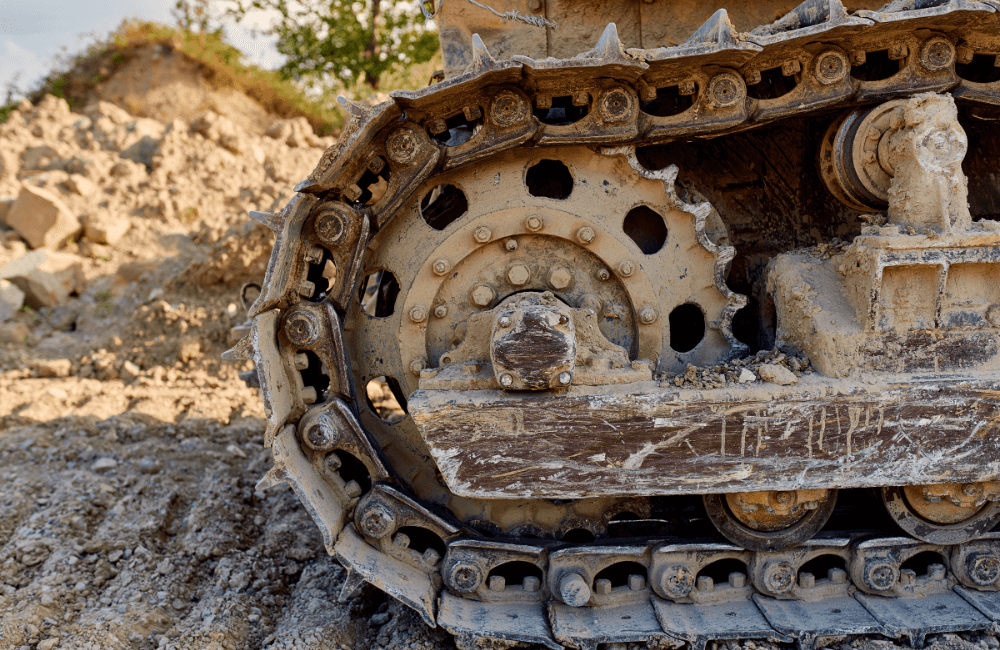

Inspect and maintain the equipment

Inspect the equipment for wear and tear, fixing any problems you identify before you take the machine on a slope.

Follow safe working procedures for heavy equipment

There are so many safety issues to keep in mind when using earthmoving equipment. Follow all safety instructions to the best of your ability, and using earth-moving equipment on hills will become a safer endeavour, too.

What Is Possible When Using Earth-Moving Equipment on Slopes & Hills

Depending on the type of equipment and the nature of the terrain, some possible actions when using earth-moving equipment on hills include:

- Levelling, compacting, and reshaping slopes to create a more stable surface for construction.

- Removing rock, soil and other materials to help shape the foundation of a landscape.

- Using specialised techniques (benching, cut and fill, etc.) to build roads and access paths on slopes.

- Moving materials up and down slopes.

- Clearing a site by removing obstructions like rocks and trees.

- Stabilising slopes using techniques like soil nailing or terracing.

What Are the Limitations of Using Earth-Moving Equipment on Slopes & Hills?

Some risks, limitations and challenges associated with using landscaping equipment on slopes include:

- Concerns with stability and safety, particularly if the ground is uneven, loose, or too steep.

- A reduced ground-bearing capacity leads to a greater risk of sinking or slipping.

- Traction issues that compromise the safety and security of the machine.

- Difficulty achieving precise grading due to the incline.

- Greater wear and tear on the equipment leads to more frequent maintenance and higher repair costs.

- Moving material up and down slopes is not the most efficient way to shift it, and doing so can lead to delays in productivity.

Dry Hire Earth-Moving Equipment at Ryno Hire

When you need earth-moving equipment that can handle all kinds of conditions, including hills and slopes, Ryno Hire is the company for you. A Brisbane-based, family-owned and operated business, we specialise in providing dry-hire machinery you can operate yourself. For most of our machines, you only need a valid open Australian driver’s licence, and you can hire what you need to complete your home renovation project.

Ryno Hire’s range of machines includes several excavator rental options, from compact ones that fit into tight spaces to those capable of serious heavy lifting. These machines also come with a range of different-sized buckets and a variety of attachments so that you can tackle a range of jobs with a versatile approach.

Our bobcat hire options are adaptable and well-suited to a range of DIY jobs. They’re strong enough for heavy lifting and hauling yet compact enough to fit into confined spaces and difficult-to-reach areas. These machines are perfect for gardening, earthmoving, construction projects, and site clean-up.

The right kind of accessories can make a world of difference to your DIY project and Ryno Hire can provide you with specialised attachment hire that includes hydraulic rock breakers, hydraulic auger drivers and drills, hydraulic rock grabs and concrete sleeper grabs.

For hire enquiries, service and repair enquiries or any other information related to finding the right equipment, contact the Ryno Hire team.